(part 1)

I'm really not into giving "step by step" instructions on how to do this, I'm more of a "here's how I got here and if you have a better way, please share" type of person.

So I started with a 97 Isuzu Rodeo Tire carrier, 8' of 1 1/4" square tubing and some 10 mm nuts(which I ditched later) and my trusty wire welder.

I took a picture(right) while I was at the junkyard for reference... Basically the body was thinner than my Jeep's sheet metal and under-structure was where the beef was, which in comparison the 1 1/4" square tubing was overkill. For a total of 5 seconds I was thinking of cutting out the Rodeo's under support, but then I remembered the Junkyard's no power tool policy, plus where would the fun be in that. Getting the tire carrier was by far the easiest part of this job.

So now I'm back in the garage and I start this job by prepping the body; I ground off the paint where I'll be welding, deciding the general location of where the carrier was going and cut holes in the body where the hinges go. On the hinge-to-body area of the carrier I started grinding the hinges flat(Rodeo's body is round/convex the Jeep is flat) to fit the hinge tight against the body. I then started making the under-body support; fitting the two pieces that fit directly against the hinges first, then dry fitting the carrier on the body, I cut and tacked the rest of the support together. Here's where I made my first mistake in not including the gasket in the fitting, but I just ended making a spacer for the under-body support to fix it.

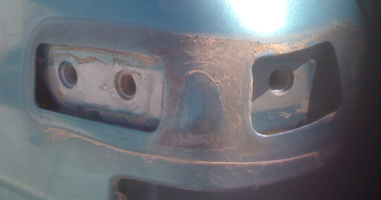

After taking the carrier off the body I finished the welds, cleaned up the under-body supports and checked the fit(left) against the hinges. I put the carrier back on the body and tacked the under-body support in place.

After taking the carrier off the body I finished the welds, cleaned up the under-body supports and checked the fit(left) against the hinges. I put the carrier back on the body and tacked the under-body support in place.

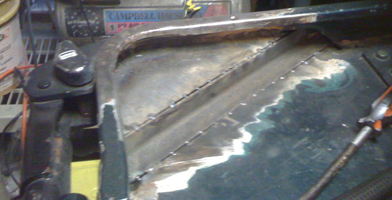

I had to raise the corner of the body 1 1/4"(right) so the under-body support could fit.

I had to raise the corner of the body 1 1/4"(right) so the under-body support could fit.

I was able to get the top hinge close to the body, but the bottom still needs work. The tailgate latch and chain need a little tweaking; I cut a 1 1/2 section out of the body's and the tailgates attachment and made new holes to attach the chain.

Sometime this week I'll post the rest which is just: mounting the latch on the tale gate, adjust, tweak, adjust, install new tail lights, and prime any bare metal.

2 comments:

wow, that's pretty impressive, I wish i had the time & skills to undertake a similar restoration project - maybe a jurassic park wrangler! I think for now i'll have to convince my wife that a new 4x4 is a good idea, without cost as an issue what would you do?!

Thanks Jim, most all of my skills were honed thanks to my cheapness and picking a rust bucket of a Jeep.

Wranglers are a great choice for a cheap Jeep now days, just look out for anything with a Peugeot BA-10. I had one as a work vehicle and put it in the shop 3 times in 6 months (Damn plastic syncros).

And for convincing your better half goes... Tell her she'll always know where you are at(Garage/shop/trail) and where your extra moneys going. :)

Post a Comment